|

BE3 BATTERY CARTRIDGES

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

HOME | AUTOMOTIVE | BLUEPLANET | ELECTRIC CARS | FORMULA E | ENERGY | INSURANCE | INDEX | SOLAR CARS |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DESIGN EVOLUTION

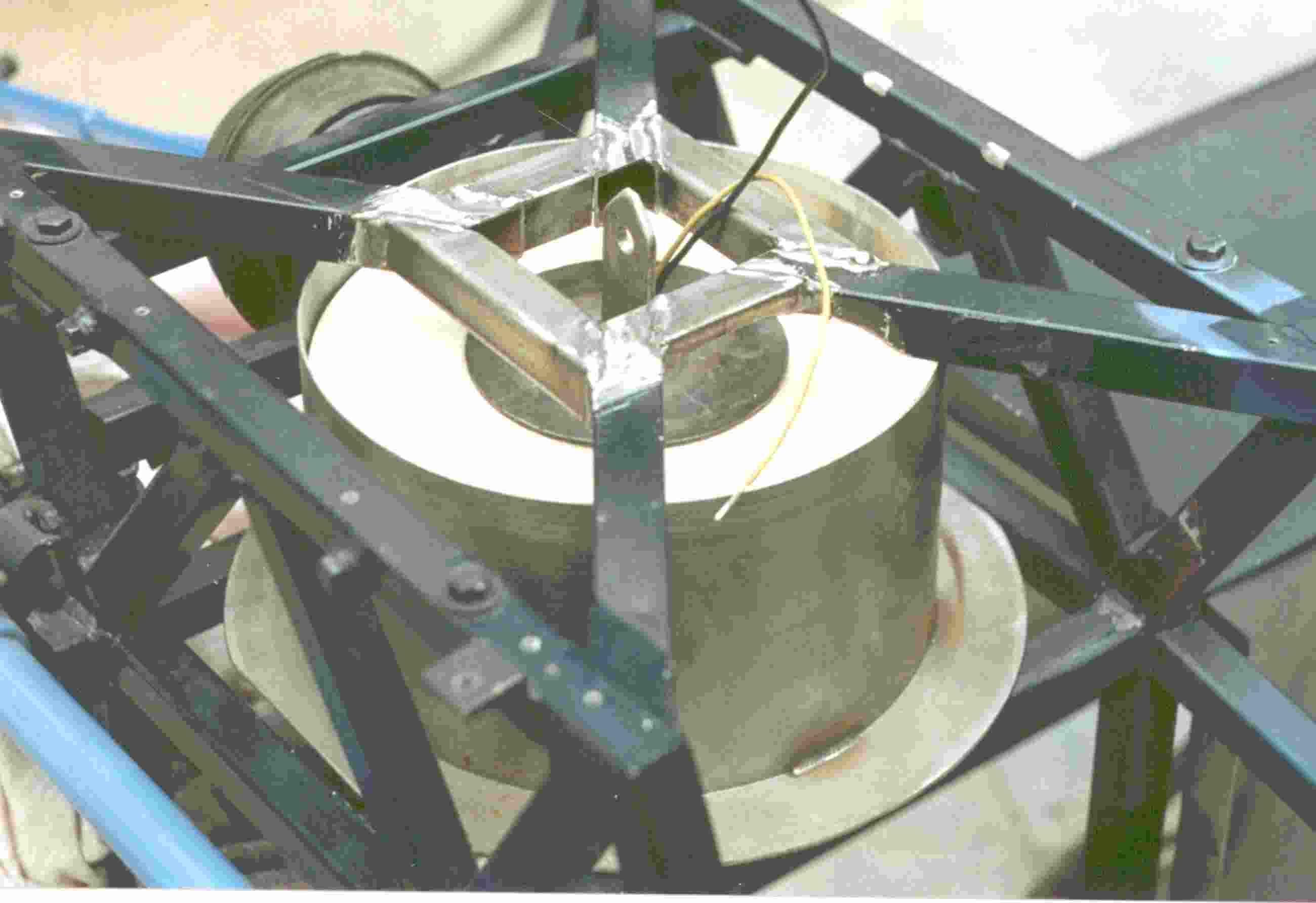

From the original (historic first) battery cartridge system of the 1990s, the latest cartridge refueling systems have come a long way. The original system illustrated above was suitable for cars which had the height to incorporate a tall loading servo, such as the BE1. This was replaced with a flat-pack electric motor servo for a rover-metro conversion demonstrator (chassis still available for research partners information).

For the future, it is necessary to standardize battery cartridges for compatibility, or other vehicles may not share system components. BE1, BE2 and BE3 are capable of utilizing the same cartridge pictured above. This cartridge may be configured for many different voltages and storage medium. BE1 was designed to use lead-acid batteries to keep costs down. The total development cost of the BE1 was in the region of £39,000, including a dedicated charger. A small price to pay for a world record contender that reached 90 mph using just 20kW motors - slightly strained, and eventually made it to 160mph with more power!

During the development of the BE2 the design bounced from Lead-Acid to Nickel-Cadmium, then quickly to Nickel-Metal-Hydride. The move to NiMh still meant that the car needed a bigger cartridge to supply the increasingly more powerful motors, and this is seen in the BE2 design drawings from 1996/7 below.

The BE1 EV battery cartridge exchange system: end view showing one NiCd battery cartridge and one load servo directly above.

The BE2 was designed for NiCd and NiMh batteries, so needed a large volume to store sufficient power, compared to Lithium, which also increased the frontal area of the car - compared to the BE3 below - which is a much more compact design. Note also, the offset tracks of the BE2 above.

The BE3 racing car can refuel in around 2 minutes by expelling one battery cartridge and replacing it with another. It does not need a complicated service station to do this. It does it with built-in load servos - so that is can turn around on the Salt Flats at Bonneville, completely recharged ready for the best of three runs. Don't you wish your EV could do that? It does not use the servo cartridge loading system seen in either the BE1 or BE2 designs. Formula E racing would be much faster using battery cartridge exchange during pit stops.

The new Lithium Polymer cells and the fall in price have changed the game. The same volume cartridge will now propel the BE3 seen below at speeds of 350+mph, so that the $ per mph ratio will improve significantly. By way of example, many solar powered electric cars use Worley Polymer cells now offering (190Wh/kg).

The Ecostar team are looking for corporate sponsors and collaborative research partners. If your company or academic organisation would like work with our group on the BE3 project, the new management team would like to hear from you.

Brochure produced for the BE1 EV LSR project by Don Wales: "..refueling system which has made this record attempt possible." The chassis design used for the BE1 and BE2 is not thought to be useable for Formula E. Racing drivers expect feet first. A suitable design is on the drawing board - for any FE team interested. BMS Ltd are looking for collaborative partners to conduct a feasibility study.

Probably the world's fastest solar powered Eco electric car: 350mph + This car's batteries are charged using natural solar energy. A green eco sporting event - looking for sponsorship for 2015/2016. Chasing the blue bird of clean air happiness - Maurice Maeterlinck.

ENERGY GENERATING-DISTRIBUTION UTILITIES

The world's fastest electric circuit racers need a system to recharge batteries instantly during pit stops. The Formula E concept design above incorporates the patent Bluebird™ instant energy transfer system - allowing EV refuelling in around 10 seconds. Get your free developer License from Bluebird Marine Systems Ltd.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

BLUEPLANET BE3 | EDUCATION | ELECTRIC CYCLES | SOLARNAVIGATOR |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The

content of this website is copyright © 1991 and 2013 Electrick

Publications. All rights reserved. The bluebird logo |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||